The Next Generation of Water Heaters from Sioux

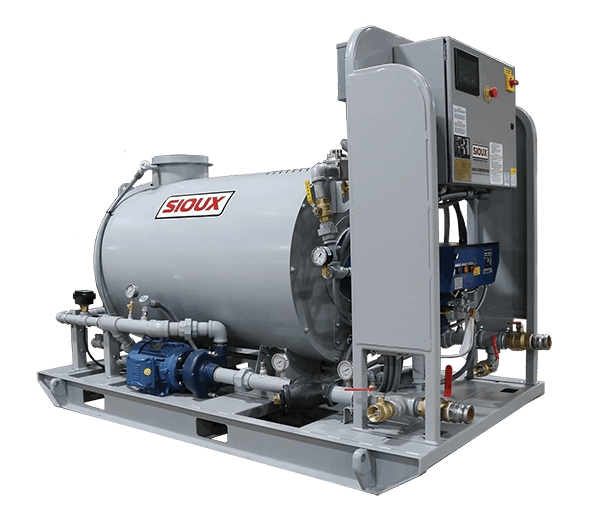

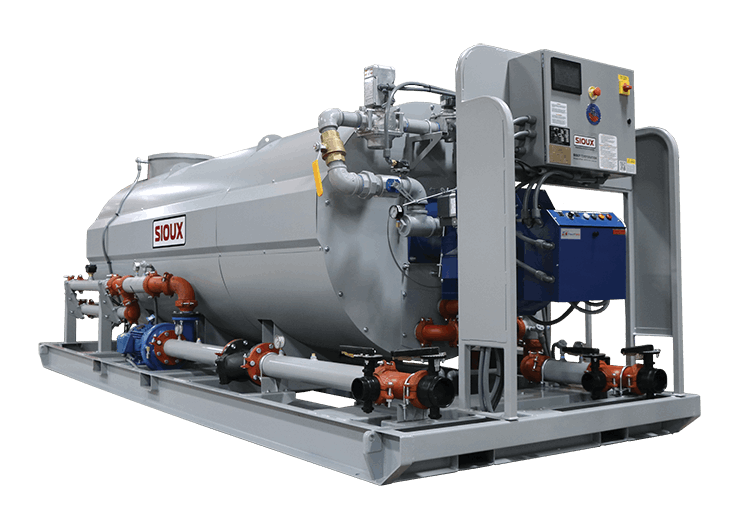

Sioux water heaters are used worldwide in a variety of industrial applications. Sioux’s NextGenTM water heaters come with advanced features to make the process of heating water safe, quick, and efficient. These horizontal heat exchanger units provide a continuous supply of hot water within minutes of startup with an efficient and simple design.

Industrial Water Heaters Engineered to Make Your Operation Run Smoother

Performance

- BTU ratings are 1.0, 1.7, 3.0, or 5.0 Million BTU/Hr heat output.

- Primary electricals are 230/1Ph/60Hz, 230V/3Ph/60Hz, 460/3Ph/60Hz, and 575/3Ph/60Hz.

- Available with Diesel, LP, Natural Gas or Combination burners.

Operation/Maintenance

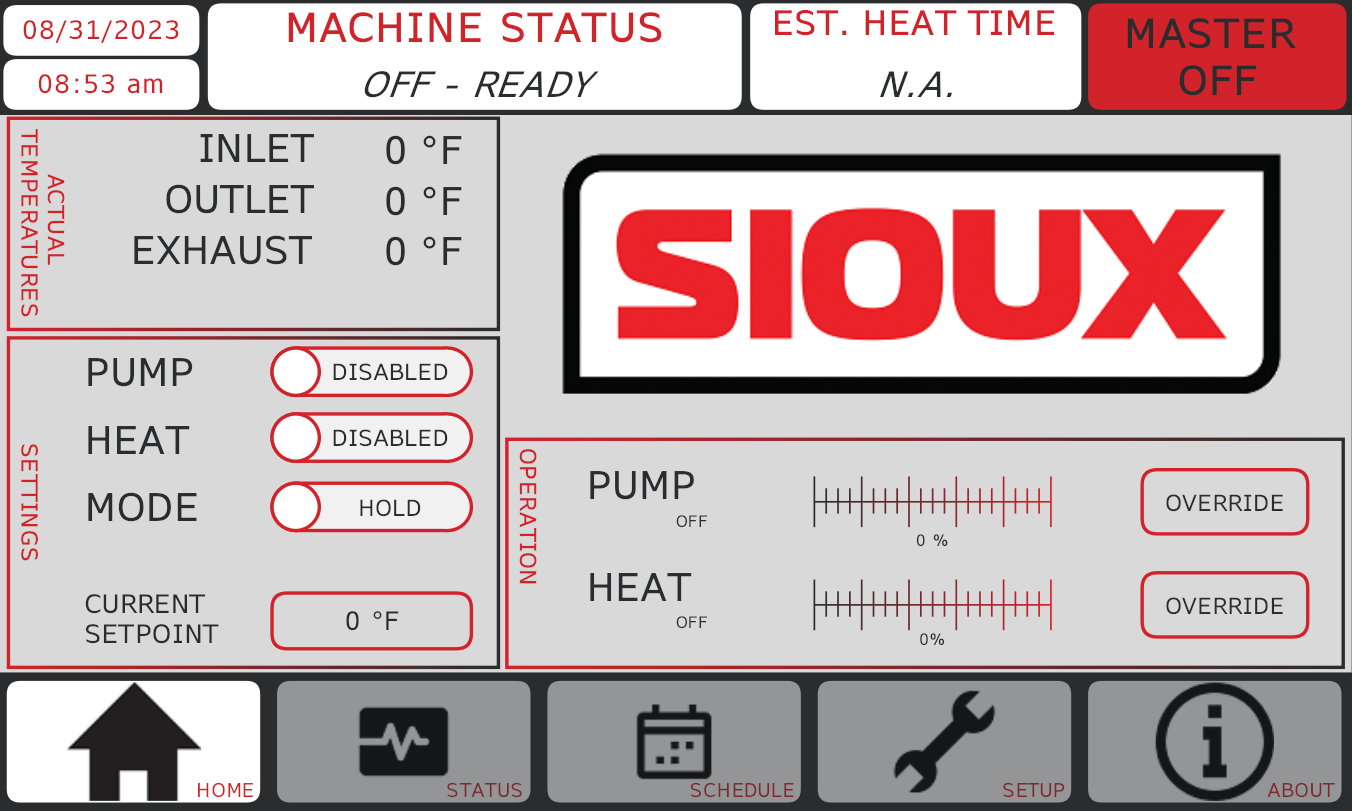

- Remote connectivity gives you the ability to monitor and operate from a remote location.

- PLC functionality provides automatic scale monitoring and notification; maintenance alerts; burner and thermocouple monitoring (including fault codes); estimated time to heat; ability to set operation schedule and tank temperature; ability to integrate operation and monitoring of Sioux Tank Skid package; and data logging.

- Variable Frequency Drive (VFD) standard on 1.7, 3.0, & 5.0 models allows the

heater to achieve higher outlet temperature in a single pass and reduces electrical consumption during idle times. - Vacuum gauges for y-strainer will indicate when clean out is required.

- Condensation outlet fitting drains condensate to a single point on the skid edge.

Safety

- Standard safety devices include emergency stop switch; exhaust temperature limit switch; inner and outer coil flow switches; and temperature limits.

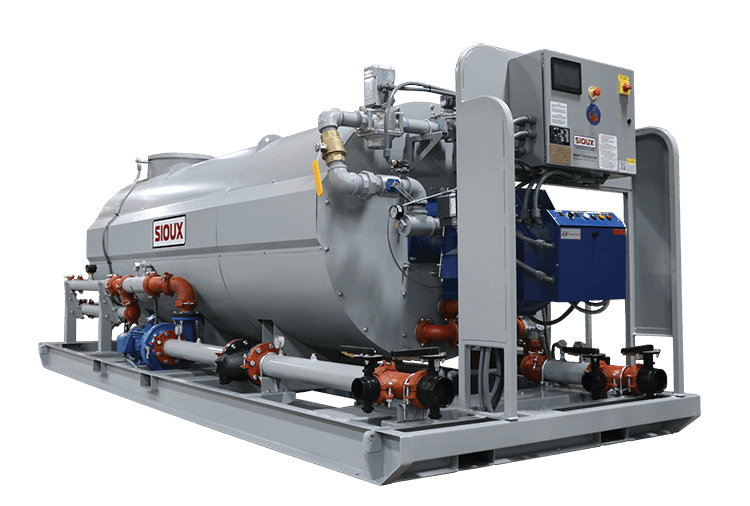

Industrial Construction

- Powder coated heavy-duty skid, built in lift points, and 4-way forklift access.

- Optimized skid dimensions and weight.

- Designed with high flow cast iron pump for long life.

- Groove fittings for easy maintenance of common service items such as coil removal and isolating inner and outer coil for winterization/blow down. Used on inlet and outlet connections on WH3.0 and WH5.0.

Flexibility

- Carbon or stainless steel heat exchangers.

- Available Lo/Hi/Lo and Modulating burners allow you to achieve higher tank temperatures.

- Alternate voltages available.

- Custom options available.

Certification & Standards

- Built to ASME Code Section IV and registered with the National Board of Boiler and Pressure Vessel Inspectors.

- Canadian Registration Number (CRN).

- Electrical panel meets UL-508a and CSA C22.2 #14.

- Sioux water heaters are engineered and built utilizing Sioux’s modern manufacturing processes.

Carbon Steel Heat Exchanger

Sioux developed the NextGenTM series utilizing decades of customer application experience. These innovative water heaters with carbon steel heat exchanger have advanced features to meet your need for efficient hot water with ease of use, monitoring, and maintenance. Sioux carbon steel water heaters provide hot water for a variety of applications.

Carbon Steel Applications

• Hot Water for Ready Mix Concrete

• Hot Water for Precast Concrete

• Process and Fluid Heating

• Industrial Manufacturing

• Frac Tank Heating

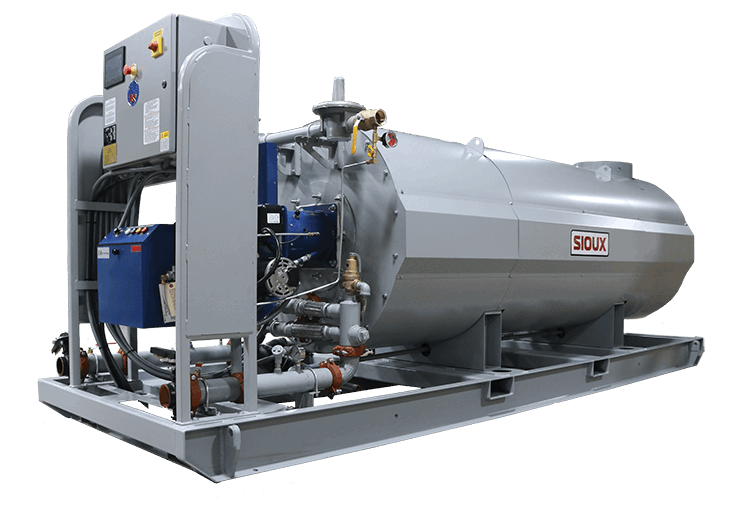

Stainless Steel Heat Exchanger

For applications that cannot utilize the standard carbon steel models, Sioux offers water heaters with Schedule 40 stainless-steel heat exchanger and non-ferrous, wetted parts. All Sioux stainless steel heat exchangers are manufactured in house. These water heaters provide the same performance and features for specific applications that require stainless steel.

Stainless Steel Applications

• Corrosive Applications

• Food & Beverage Manufacturing

• Pharmaceutical Manufacturing

• DEF Production

• Specialized Process and Fluid Heating

• CIP or COP Cleaning in Processing Facilities

| Model # | fuel | heat output btu hr | maximum flow rate gpm | volts | Compare |

|---|---|---|---|---|---|

| WHC1.0PG | LP / NG | 1,000,000 | 90 | 208/230/460/575 | |

| WHC1.0PD | Diesel | 1,000,000 | 90 | 208/230/460/575 | |

| WHC1.0PC | Combo | 1,000,000 | 90 | 208/230/460/575 | |

| WHC1.7PG | LP / NG | 1,700,000 | 105 | 208/230/460/575 | |

| WHC1.7PD | Diesel | 1,700,000 | 105 | 208/230/460/575 | |

| WHC1.7PC | Combo | 1,700,000 | 105 | 208/230/460/575 | |

| WHC3.0PG | LP / NG | 3,000,000 | 180 | 208/230/460/575 | |

| WHC3.0PD | Diesel | 3,000,000 | 180 | 208/230/460/575 | |

| WHC3.0PC | Combo | 3,000,000 | 180 | 208/230/460/575 | |

| WHC5.0PG | LP / NG | 5,000,000 | 325 | 208/230/460/575 | |

| WHC5.0PD | Diesel | 5,000,000 | 325 | 208/230/460/575 | |

| WHC5.0PC | Combo | 5,000,000 | 325 | 208/230/460/575 | |

| WHS1.0PG | LP / NG | 1,000,000 | 90 | 208/230/460/575 | |

| WHS1.0PD | Diesel | 1,000,000 | 90 | 208/230/460/575 | |

| WHS1.0PC | Combo | 1,000,000 | 90 | 208/230/460/575 | |

| WHS1.7PG | LP / NG | 1,700,000 | 105 | 208/230/460/575 | |

| WHS1.7PD | Diesel | 1,700,000 | 105 | 208/230/460/575 | |

| WHS1.7PC | Combo | 1,700,000 | 105 | 208/230/460/575 | |

| WHS3.0PG | LP / NG | 3,000,000 | 180 | 208/230/460/575 | |

| WHS3.0PD | Diesel | 3,000,000 | 180 | 208/230/460/575 | |

| WHS3.0PC | Combo | 3,000,000 | 180 | 208/230/460/575 | |

| WHS5.0PG | LP / NG | 5,000,000 | 325 | 208/230/460/575 | |

| WHS5.0PD | Diesel | 5,000,000 | 325 | 208/230/460/575 | |

| WHS5.0PC | Combo | 5,000,000 | 325 | 208/230/460/575 |

Have a Question?

Sioux serves a wide range of industries with our decades of experience, reliable products, and value added services that help companies every day around the world.

Why Sioux?

Sioux's products are built for the concrete, petroleum, mining, rail, greenhouse, food & beverage, and manufacturing industries with the highest quality and durability in mind. We strive to make sure our customers have the safest and most efficient equipment they can rely on year after year.